An Extruded Heat Sink is an essential component used in various industries to manage heat dissipation. It is designed to improve the performance and longevity of electronic devices by maintaining an optimal operating temperature. In this article, we will explore the structure, applications, and advantages of using an Extruded Heat Sink in your designs.

What is an Extruded Heat Sink?

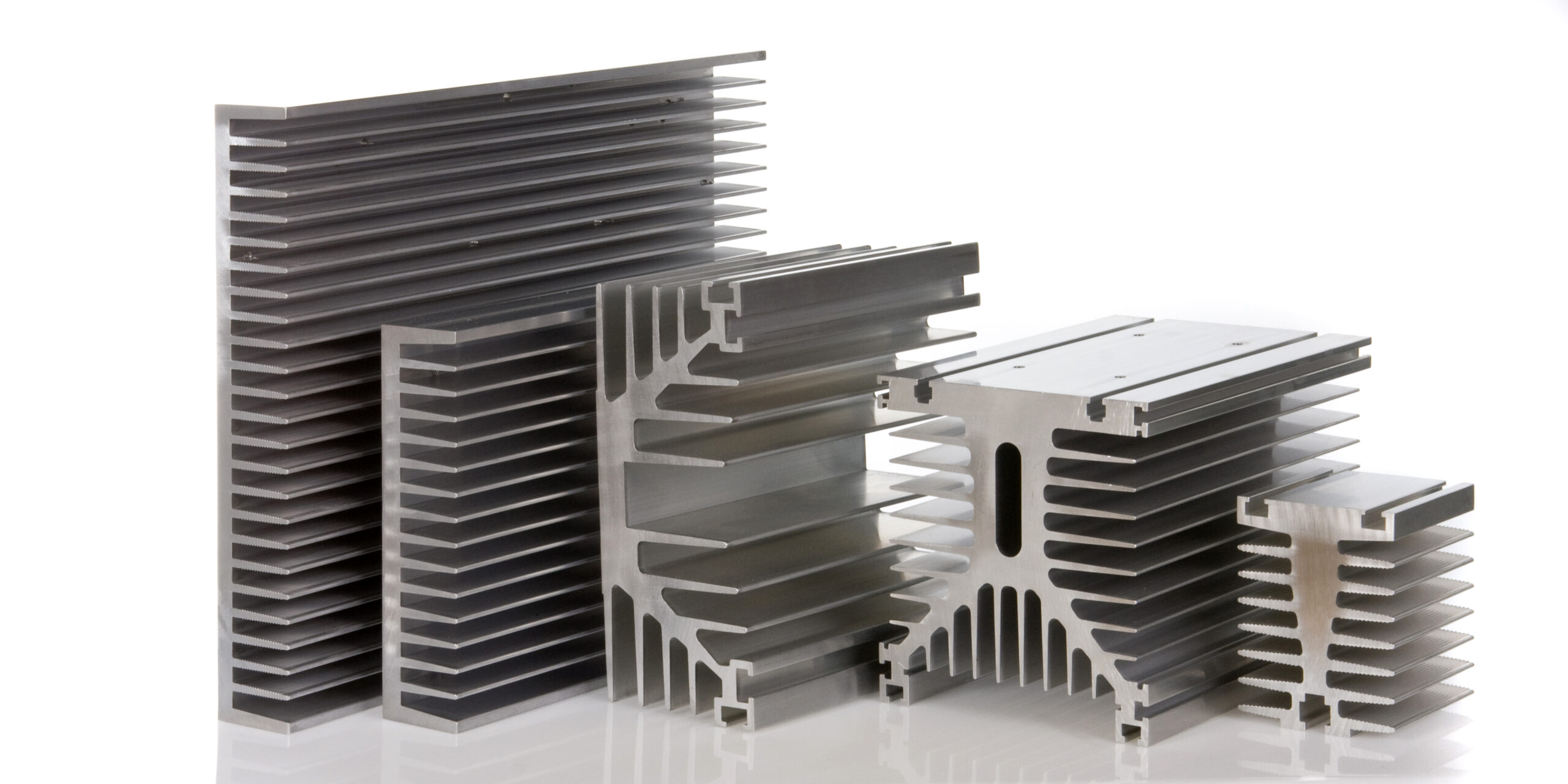

An Extruded Heat Sink is a type of thermal management solution made from metal, usually aluminum, which is extruded into specific shapes and profiles to maximize the surface area for heat dissipation. The extrusion process involves forcing the material through a die to create the desired shape. This technique allows for the production of complex and precise shapes that help efficiently spread and dissipate heat generated by electronic components like processors, LEDs, and power supplies.

The primary function of an Extruded Heat Sink is to draw heat away from a heat source and release it into the surrounding environment. By increasing the surface area and providing paths for heat to flow away from sensitive components, the Extruded Heat Sink prevents overheating, which could otherwise lead to performance issues or device failure.

The Structure and Materials of Extruded Heat Sink

Extruded heat sinks are typically made from lightweight yet thermally conductive materials like aluminum. Aluminum is preferred because of its excellent thermal conductivity, low weight, and cost-effectiveness. The process of extrusion enables the creation of heat sinks with fins and other features that further enhance the ability to dissipate heat.

The shape of the heat sink, such as flat, pin, or finned, can vary depending on the specific needs of the application. The fins, often placed in parallel, provide a large surface area that helps transfer heat away from the source. The structural integrity of the Extruded Heat Sink is critical, as it must endure the stresses and thermal cycles encountered during normal operations.

Applications of Extruded Heat Sink

The Extruded Heat Sink is widely used in industries ranging from consumer electronics to automotive. In electronics, they are employed in devices such as computer processors, power amplifiers, and LED lights. The goal is to keep these components cool and functioning efficiently, thus preventing overheating.

In automotive applications, Extruded Heat Sink helps in cooling electronic control units (ECUs) and battery systems for electric vehicles. These systems generate a significant amount of heat, and the heat sink ensures they operate at safe temperatures, prolonging the life of the components and enhancing vehicle performance.

Moreover, Extruded Heat Sink is also seen in the telecommunications industry, where devices like network switches and routers rely on effective thermal management to ensure reliability and long-term functionality.

Benefits of Using an Extruded Heat Sink

One of the significant benefits of an Extruded Heat Sink is its cost-effectiveness. The extrusion process allows for the production of heat sinks in large volumes, which reduces manufacturing costs compared to other methods, such as machining or casting. Moreover, the precise shapes and sizes produced during extrusion ensure that the heat sink can be tailored to meet specific requirements, enhancing the thermal performance.

Another advantage is the energy efficiency of Extruded Heat Sink. By preventing overheating, it ensures that devices continue to operate efficiently, consuming less power and extending their operational life. This contributes to the overall sustainability of electronic products.

Additionally, the lightweight nature of the Extruded Heat Sink makes it easier to integrate into various designs without adding unnecessary weight. This is particularly important in industries like aerospace and automotive, where weight is a critical factor in performance.

Why Choose an Extruded Heat Sink for Your Projects?

Choosing an Extruded Heat Sink for your thermal management needs ensures that you are investing in a solution that offers both high performance and long-term reliability. The versatility of extrusion allows manufacturers to create heat sinks in a wide range of shapes, sizes, and configurations, making it ideal for a broad spectrum of applications.

By selecting an Extruded Heat Sink, you also benefit from improved energy efficiency, reduced operational costs, and enhanced product longevity. Whether you are designing a consumer gadget, an industrial system, or an automotive component, the Extruded Heat Sink will help you maintain optimal performance while keeping temperatures in check.

In conclusion, an Extruded Heat Sink is an indispensable tool in the thermal management of modern electronic devices. Its ability to effectively dissipate heat, coupled with its cost-effectiveness and versatile design, makes it a top choice for various industries. If you are looking to enhance the performance and longevity of your products, an Extruded Heat Sink could be the solution you need.